NEWS DETAIL

Quartz has quietly powered the evolution of solar energy for decades. Its exceptional thermal stability and optical clarity make it more than just a raw material—it’s a critical enabler of high-efficiency, durable photovoltaic (PV) modules. Whether you’re a procurement manager evaluating suppliers or a process engineer optimizing production, understanding quartz’s role helps you secure better yields, longer lifetimes and stronger ROI on your solar investments.

Why Does Quartz Matter?

Quartz (silicon dioxide, SiO?) combines high melting point, chemical inertness and excellent optical transmission in one package. In PV manufacturing, temperatures regularly exceed 1,400 °C—well above the limit of many ceramics—so quartz’s ability to withstand thermal shock protects both equipment and silicon feedstock. Meanwhile, its transparency to ultraviolet and infrared wavelengths ensures uniform heating and precise diffusion during crystal growth. Without quartz, modern solar technology would face lower throughput, higher contamination and reduced cell efficiencies.

How Quartz Is Used in Solar Panel Manufacturing

-

Crystal Growth Crucibles: Ultra-pure quartz crucibles hold molten silicon during the Czochralski process, shaping ingots that are later sliced into wafers.

-

Diffusion Furnaces & Tubes: Quartz tubes convey gases and support wafers as dopants diffuse into silicon. Their smooth interior walls resist chemical attack and minimize particle generation.

-

Annealing Chambers: Post-doping heat treatments rely on quartz windows and liners to deliver controlled infrared radiation, relieving stress in wafers without introducing impurities.

-

Encapsulation Components: Quartz glass sometimes forms part of the optical assembly in advanced concentrator photovoltaics, thanks to its UV stability.

Each application leverages quartz’s purity and strength, ensuring that solar cells emerge from each step with minimal defects and maximum performance.

Benefits of Using Quartz in Solar Technology

Enhanced Cell Efficiency

Uniform heating and low contamination yield more defect-free wafers, directly boosting conversion rates.

Improved Equipment Longevity

Resistance to thermal cycling and aggressive process gases reduces furnace maintenance and downtime.

Consistent Production Yields

Stable optical properties guarantee repeatable results, so manufacturers hit target throughput without surprise failures.

Lower Total Cost of Ownership

Fewer replacements and higher yield mean that quartz may carry a premium per kilogram—but pays for itself over thousands of production cycles.

Why Purity of Quartz Matters

Not all quartz is created equal. Trace metal impurities (iron, aluminum, sodium) can diffuse into silicon, creating recombination centers that sap cell performance. High-purity grades—often labeled 6N (99.9999 % SiO?) or higher—are essential in PV applications. These materials undergo multiple acid leaches, high-temperature treatments and cleanroom-grade fabrication to strip away contaminants. Investing in ultra-pure quartz delivers measurable improvements in minority carrier lifetimes and open-circuit voltages, the two hallmarks of top-tier solar cells.

Quartz Products Used in the PV Industry

-

Quartz Crucibles: Sized for ingot dimensions from 100 mm to 300 mm, with wall thicknesses tailored to thermal profiles.

-

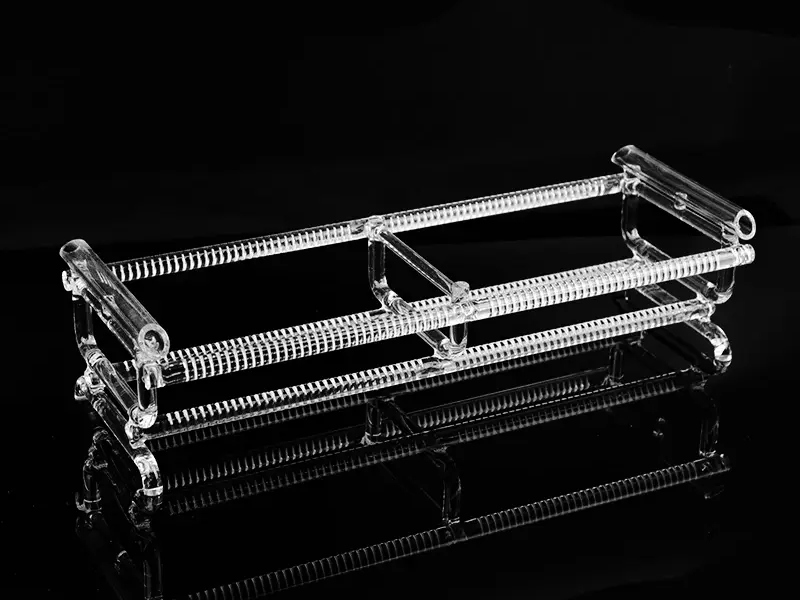

Quartz Boat Carriers: Custom fixtures that hold wafers horizontally or vertically through diffusion and annealing steps.

-

Quartz Tubes & Furnaces: Precision-made tubing for gas flow and heat treatment, often in continuous-feed reactor designs.

-

Quartz Windows & Viewports: Optical-grade panes for process monitoring, designed to resist clouding under UV exposure.

-

Quartz Insulators & Seals: Components that maintain atmosphere integrity in vacuum or inert-gas furnaces.

Selecting the right supplier means assessing not only purity and geometry but also fabrication controls, surface finish and packaging protocols—each factor can influence your downstream yields.

Quartz’s unique combination of thermal, chemical and optical properties makes it indispensable to PV manufacturing. By focusing on high-purity materials and the right product formats, solar producers can achieve peak efficiencies, lower costs and longer equipment lifespans—key advantages in today’s competitive renewable energy landscape.

DKEQ is a wholesale quartz products manufacturer. We offer customized PV quartz products. Please feel free to contact us!